News

Top 10 Truck Driving Jobs

Take a moment and think, what is one industry that has been behind the success of every other business in the world? That’s right, the trucking industry.

There’s no denying that the profession of trucking has and continues to be one of the largest contributors to the American economy. Without it, millions of hardworking individuals would be without a job, and other businesses, like Amazon and Walmart, would collapse due to limited resources and the inability to ship. Different vital industries like construction, oil and gas, and automotive would also suffer greatly without trucking. And without the success of these enterprises, America’s economic infrastructure would ultimately give way.

-> What Would Our World Be Like Without Truck Drivers?

So you see, truck drivers indeed are the backbone of our society, the oil that keeps the machine running smoothly, if you will. Fortunately, the essential occupation doesn’t seem to be going anywhere, making it one of the most secure jobs in the world. The only thing left to do is pick the type of driver you would like to be. No pressure.

What are the Different Types of Truck Drivers?

Flatbed Truckers

Built differently than traditional tractor-trailers, flatbed trucks typically require additional training or education to execute safe and effective operations. On top of that, their drivers must thoroughly understand what they will be hauling and how to secure it properly since flatbed loads must be secured differently from tractor-trailer cargo. Typical freight includes vehicles, military vehicles, oversized freight, and oddly shaped cargo that doesn’t fit well on other truck types. Fortunately, since flatbed trucking is more demanding, it typically offers higher pay than different driving positions.

Dry Van Truckers

Dry van trucking is an excellent position for those entering the occupation with minimal experience. These drivers are typically responsible for single trailer rigs that contain items like non-perishables and dry goods. A bonus for this title is that drivers are often not accountable for unloading upon arrival.

-> Buying vs. Leasing a Semi-Truck: An Owner Operator’s Guide

Tankers

If dry goods aren’t your thing, you may be interested in becoming a tanker. Tankers primarily transport a variety of liquids, including gasoline, chemicals, and even milk. However, there are times that tankers will also be responsible for hauling dry products like cement or sugar. But in some cases, these drivers could also be dealing with highly explosive chemicals and gases. Since moving this delicate cargo can be, in some ways, dangerous, special training is required before starting this job.

Freight Hauler

Otherwise known as commercial truckers, freight haulers specialize in moving cargo that does not fit into a specified category like reefers and tankers. These drivers need to be flexible and good with change.

-> Post-Pandemic Era for the Freight Industry?

Refrigerated Freight (Reefer Drivers)

Refrigerated freight truckers have a pretty strenuous position. They are responsible for hauling loads that need to be kept at specific temperatures, like food, meats, highly perishable goods, medical products, and body products. That all being said, it’s crucial that reefer drivers know how to regulate the trucks’ temperatures, monitor for fluctuations, and adequately store freight for best refrigeration and temperature stability. Like flatbed drivers, reefers are often paid more than other types of drivers due to the amount of responsibility they are charged with.

Local, Regional, and OTR Drivers

Local, regional, and OTR drivers are labeled or defined by the mileage they acquire. While local drivers only haul within a city, regional drivers often move freight throughout an entire state or metropolitan area. For OTR drivers, they have the potential to be given routes across the United States.

-> Why Owner/Operators Should Run Hard This Holiday Season

Auto Haulers / Car Haulers

Auto haulers, are given special trailers that can hold an abundance of various automobiles. Where they are taking these automobiles varies. Drivers may be transporting from auctions, local vehicle lots, or ports; you name it. With tens of thousands of dollars on the line, you better believe this job comes with a more than fair wage.

Hazardous Materials Drivers

The typical hazardous materials driver will haul fuel, compressed gas, chemicals, waste, and other flammable/combustible materials. It’s crucial for drivers to be knowledgeable about the contents they’re hauling and how to handle them safely in the event of an emergency. To ensure everyone’s safety, special training, certifications, and/or permits will be required.

-> 5 Things Owner/Operators Should Do to Achieve Success

LTL Freight Truckers

LTL, or Less Than Truckload, drivers move smaller freight and don’t need to go as far as standard shipments. With their cargo being on the smaller side, they will typically have multiple stops to make in one day and are generally responsible for unloading their own freight.

Low Boy

The trailers that sit close to the pavement and the truckers who drive them are low boys. These rigs sit lower to accommodate taller equipment or cargo and provide stability with a lower center of gravity. In most cases, these trailers are hauling overly large freight, like manufactured homes, construction equipment, etc. However, these low boys don’t fly solo. They often are escorted by vehicles with flashing lights and signs that read something like ‘Caution’ or ‘Oversized Load.’

Which Type of Truck Driver Should I Choose?

It’s clear that trucking is not only a high-demand profession, but it is a career that offers flexibility, the opportunity to travel, and the chance to meet and develop camaraderie with fellow drivers. Regardless of your age, gender, or educational background, your chances of achieving success are just as probable as the next. Best of all, the variety of job titles allows you to choose an occupation that best suits your life.

Before deciding, you’ll want to consider personal factors such as your location, risk tolerance, situation, and experience. For example, if you’re new to the industry, you won’t want to dive headfirst into something like transporting hazardous materials. There is a great likelihood that you will hold multiple positions with various skill requirements throughout your career. So, use this list as a guide to discover where to start or where to go next.

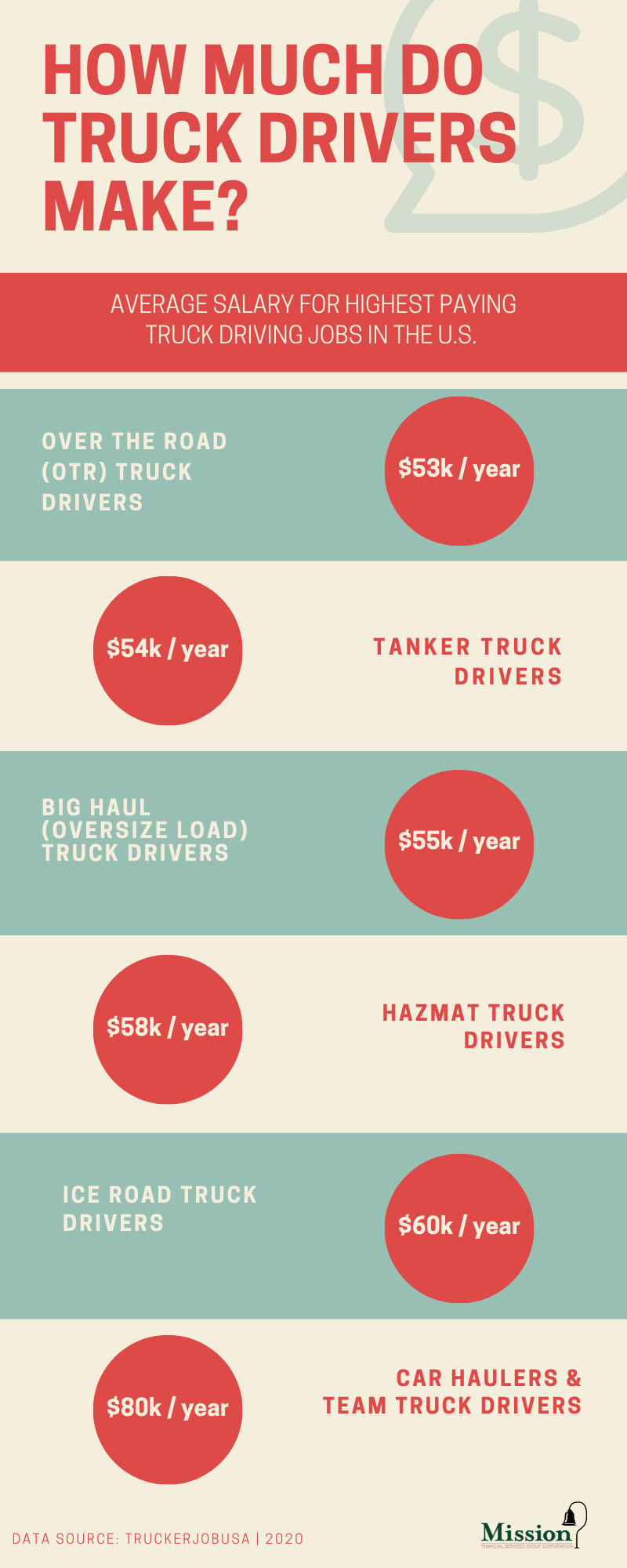

Want to know how much truck drivers make? Download our infographic!

How to Save on Diesel Emissions Repair Costs

In 2005, diesel engine manufacturers weren’t entirely sure how to attain the EPA’s future emissions regulations and standards. Ultimately, they were faced with having to think on their feet and start inventing new parts and systems if they planned on staying in business.

Not surprisingly, the industry delivered. The invention of SCR systems used fluid formulas to scrub nitrous oxides out of the diesel exhaust smoke chemically. This led to cleaner air and gave a much-needed boost to big rigs’ fuel economy. Experts say aftertreatment systems reduced harmful emissions by up to 90% for hydrocarbon and carbon dioxide and up to 50% in particulate matter.

While trucking companies and engine manufacturers feel the systems have proven safe and reliable, many aren’t fans of the amount of maintenance requirements to keep them functioning correctly.

→ Top ways to prepare for roadside inspections

The reality of diesel emissions maintenance

Many don’t realize that before implementing the aftertreatment systems, private long-haul fleets were averaging around $1,200 per month on exhaust system maintenance, such as replacing a rusted or cracked pipe or fixing a turbo failure. Once the SCR systems were installed, companies were hit with an average of $27,000 per month in repairs. This 1,837% increase in expenses left fleet owners at a loss for words. We know what you’re thinking—how does any amount of maintenance add up to almost $30K per month? For optimal performance, today’s diesel emissions systems require EGR coolers and valves, diesel particulate filters, DEF dosing systems, and several sensors to work together in perfect harmony. If one item malfunctions or needs repair, the system will fail and force the heavy-duty rig and its driver to cease all operations, leaving the fleet owner with a severe financial burden.

→ Tips for tire maintenance and repair

The actual cost of diesel emissions repairs

In 2017, the American Trucking Associations’ Technology & Maintenance Council began monitoring various repairs and the costs associated with them to help fleets analyze how their fleets’ performance could be improved and, in turn, limit expenses. When data was first collected, exhaust system repairs were approximately $513; a year later, they increased by 27%, putting them at $405 per repair. Today, the costs are still rising as new technology, parts, and companies emerge.

Understandably, fleet owners and operators are tired of these looming and ever-increasing prices. However, the TMC found that these repairs wouldn’t be necessary with a bit of forethought.

Heavy-duty emissions maintenance tips

To combat costs and constant repairs, fleets have decided to operate outside of the aftertreatment system manufacturer’s recommendations. While the suggested intervals for repair and maintenance are fair in ideal scenarios, companies have quickly realized that it’s more effective to operate based on actual variables. These variables include truck usage, geography, fuel quality and consumption, weather conditions, applications, and more. After seeing how all these factors played a role in SCR system repairs, it became clear that investments in in-house equipment and technicians were necessary.

Another way to limit expenses is to perform routine cleanings, checks, and maintenance every 100,000 miles instead of the OEMs’ recommended 400,000 miles. Companies have also started looking at other vehicle functions to determine if they may be behind emission failures. For example, a simple fluid leak could be the cause of a reoccurring problem versus a malfunctioning sensor.

All of these preemptive measures will undoubtedly reduce costs and downtime, allowing more money to be available for improving your fleet.

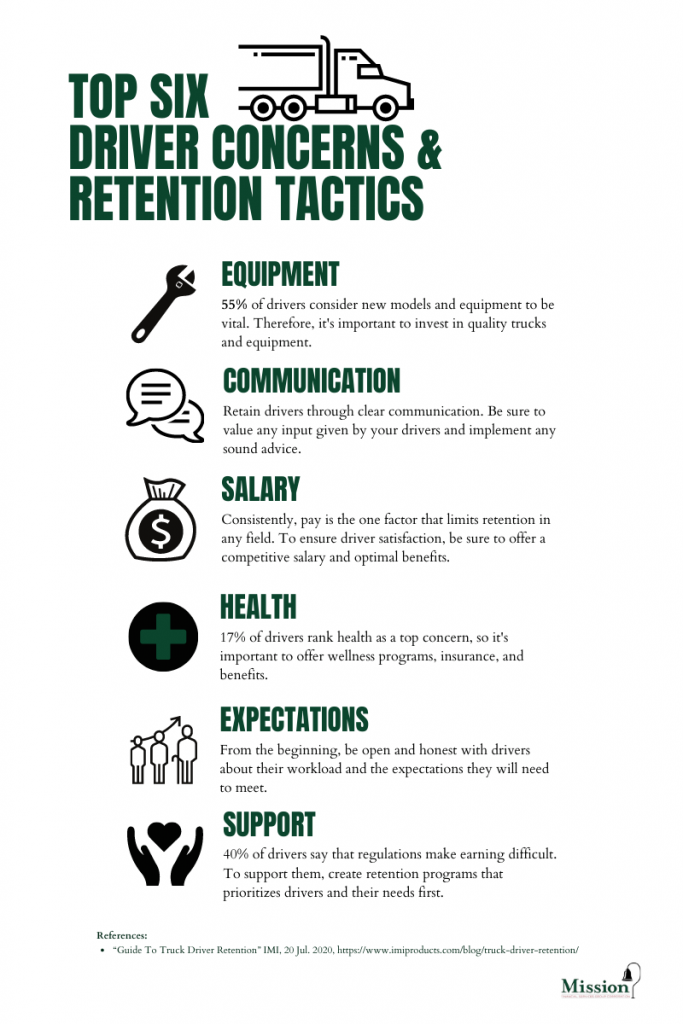

How to Retain Your Top Drivers During a Shortage

This past year came with several challenges and transformed the shipping industry in more ways than one. Since July, truckload rates are up 40-50% and rising due to retailers’ attempts to restock their inventory to meet the heightened demand. With these businesses reopening and the need for shipping at an all-time high, now is the perfect time for truckers to find multiple offers for work.

However, despite the wealth of opportunities for drivers, many companies are experiencing high turnover rates. Not only that, but the industry is facing a driver shortage that many professionals feared at the start of the pandemic. While these scenarios don’t seem ideal for operators, there are ways to ensure driver retention. Here are some best practices for retaining your best drivers.

→ Finding the fix for the national driver shortage

1. Invest in your drivers.

In most industries, having the best equipment and supplies is essential to running a successful business and retaining employees. Inadequate equipment and low maintenance are significant reasons why many truckers are abandoning their fleets and employers.

It’s proven that when companies provide new equipment and proper maintenance, drivers can work more and, in turn, earn more money. If your goal is to keep your employees on and happy, you may want to consider investing in them and the tools they need to succeed.

The top investments to make include:

- Newer truck models.

- Comfortable seating.

- Auxiliary power units (APUs).

2. Set clear communication standards.

Many would agree that establishing communication standards is key to having a healthy work environment and a functioning team. In the trucking industry, clear and concise communication is invaluable. To improve retention and team-building, opt for two-way communication with direct channels and consider instilling committees to handle any feedback or peer input to allow for internal cohesion. Over time, you will see improved efficiency and excellent communication skills.

→ Employment Challenges Facing the Trucking Industry

3. Offer competitive pay.

Possibly the most obvious way to retain your drivers is through competitive pay. Many owners and operators found pay to be the single factor that drives retention downward. Try offering pay based on a guaranteed minimum mile per week versus the non-reliable high pay per mile. A set mileage will provide your drivers with more stability and keep them happy and willing to do their job. You should also consider offering health insurance packages and/or retirement plans, depending on the size of your fleet. The more you can contribute financially; the more inclined your drivers are to maintain their loyalty.

4. Prioritize health.

Approximately 50% of drivers consider their health one of their top three concerns when considering joining a new fleet. That being said, it’s essential to promote good health by equipping all trucks with functional exercise equipment, offering wellness programs that encourage healthy eating habits and an active lifestyle, and scheduling free health screenings for all drivers. These screenings will ensure optimal health and act as preventative care that keeps your drivers on the road and out of the doctor’s office.

5. Set realistic expectations.

When it comes to any job, transparency and clear expectations are a must; this standard does not change in the transportation industry. Within the first 90 days of employment, drivers will be able to tell if a job is genuinely how it was described, meaning misrepresented positions could lead to higher turnover rates. To avoid this, be upfront with new drivers about the number of miles they can anticipate, compensation, and company culture.

Another way to ensure retention is by instructing recruiters to provide accurate information when finding fleet operators. Instead of paying your recruiters on a “per hire” basis, offer a flat salary to encourage finding the best candidates instead of collecting drivers like bounties.

6. Support your employees.

Lastly, be sure to reward your drivers’ performances. Offering support and encouragement may seem fickle, but it can be the difference between a semi-operational and fully operational fleet. Experts have gathered that a 10% raise could cure the current driver shortage, although many drivers say that a simple show of appreciation could hold the same power as a raise or promotion.

It’s true, a supportive company culture can lead to excellence through and through. Instruct your fleet managers to monitor your drivers’ key performance indicators or KPIs and their performance through data-driven observations, such as positive customer reviews. You should also consider implementing safe driver programs that reward your fleet operators for minimal idling and safe driving practices.

Where Did All of the Trucks Go?

Inventory Shortage Continues to Disrupt the Auto Industry

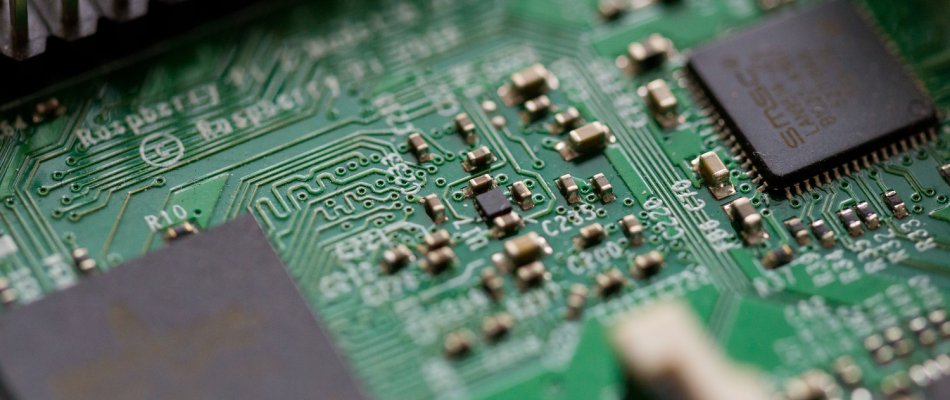

The COVID-19 pandemic has affected numerous industries and led to several issues, including a vehicle shortage that has rocked the automotive industry. To combat financial loss due to global shutdowns, dealers pushed incentives and financing offers to encourage buyers. Once government stimulus checks were distributed, consumers were more than happy to invest in new and used rigs. While this feeding frenzy helped dealers keep their heads above water during the stay-at-home orders, they didn’t anticipate a global microchip shortage that would cause significant production delays upon reopening.

With this supply not keeping pace with demand, and manufacturers prioritizing smaller vehicles for individual buyers, commercial fleet operators are left feeling the sting from this shortage. So, what can we expect moving forward? Let’s find out.

-> Used Truck Prices Continue to Skyrocket

What’s causing the vehicle shortage?

There are a few things responsible for the current state of the automotive industry. For starters, the microchips used in many vehicle components are manufactured overseas, with Taiwan contributing 63%, South Korea at 18%, and China at 6%. With the world being globally affected by the pandemic, many manufacturing plants ceased production until cases slowed down. Natural disasters have also impacted the domestic inventory. In February of 2021, Texas was forced to halt production and close a Samsung plant due to severe freezing.

Aside from the microchip insufficiency, dealers have also played a role in this vehicle shortage. At the start of the pandemic, many sellers struggled to move inventory due to quarantine restrictions and stay-at-home orders. Instead of losing their businesses, they chose to offer extreme incentives and too-good-to-be-true financing plans. Unfortunately, they kept these deals running for a little too long, and their inventory was cleared out or severely depleted. And before the stock was able to circulate back into the lots, the semiconductor shortage hit and took down new vehicle production with it. So, where do we go from here?

-> How the Gas Shortage has Affected the Trucking Industry

How is the auto industry responding?

As we navigate the lingering effects of the COVID-19 pandemic, manufacturers and the U.S. government are working to solve this shortage issue. Below, we will break down their plans.

- Automaker Action Plan: Currently, automakers are working to fulfill dealers’ needs and buyers’ wants by continuing to build out vehicles and forgoing the components that require the semiconductor microchip. Manufacturers are also allocating what they have in the way of microchips to high-demand vehicles and adjusting the availability of certain automobile features, packages, and options. While this action plan offers some much-needed relief, it is not enough to solve commercial fleet operators’ problems.

- Government Action Plan: Fortunately, the U.S. government recognized the geopolitical nature of this scarcity and acted early in resolving the issue. With the majority of the microchips being produced in China and Korea, our government needed to invest in domestic semiconductor production to regain the upper hand in inventory levels, which is precisely what they did. The U.S. Senate passed a $190 billion legislation package to compete with foreign tech, with $54 billion allocated to domestic manufacturing of semiconductors and telecommunication equipment. While the bill still needs to survive the House of Representatives, President Biden has voiced his support for the bill.

When will fleet inventory return to normal?

Within the first half of 2021, auto sales have mostly recovered despite the technology shortage. Unfortunately, the sales of commercial vehicles have not responded in the same manner. So far, only 14% of vehicles were sold to fleet consumers. Now, automakers are having to prioritize microchip distribution to recuperate inventory levels. Many are allocating supplies to higher-end models and leaving commercial operators at the mercy of a waiting list.

Moving forward, it’s unlikely that we will ever surpass the industry’s previous standards or return to normal inventory levels. According to industry insiders, the microchip shortage could last another four months, and while recovery efforts are vast, they’re not enough to meet the ever-increasing demand. However, companies and manufacturers are predicting supply improvements by the first quarter of 2022. While there is no sure way of knowing the exact numbers, operators should be prepared to face this shortage until 2023.

Post-Pandemic Era for the Freight Industry?

The COVID-19 pandemic will surely go down in history as one of the most chaotic times the world has ever experienced. Essential workers sacrificed their health and stretched themselves thin for the American people, spending many hours away from their homes to meet the increasing pressure brought on by restrictions and regulations.

As people begin recovering from the effects of the pandemic and vaccines are distributed throughout communities, many industries are forced to relook at how they handle business. So, what does this mean for the trucking industry in this post-pandemic era?

Why Fleets are Experiencing 2021 Prosperity

Since the beginning of the pandemic, consumers have continuously relied on online platforms for their wants and needs. And as businesses open back up, many flock to the sight of normalcy, leaving companies in need of constant supply. This consistent demand has fallen on the backs of truckers nationwide and has many freight companies stretched thin.

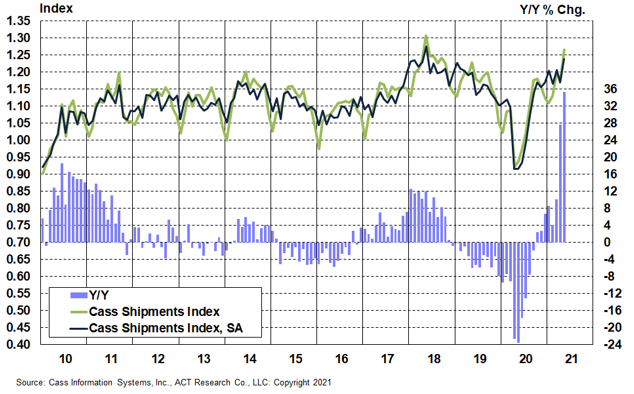

In May alone, total spending on freight surged to a record 50% year over year, while shipping volumes swelled to a whopping 35%, making this year the second-highest index level ever recorded. “It’s safe to say the pandemic recovery is progressing much faster than the recovery from the Great Recession,” according to the Cass Freight Index.

However, this overwhelming need has ultimately led to an intense growth in domestic shipping rates, and in turn, a shortage in freight vehicles and drivers. With consumerism at an all-time high, the demand for technological advances, logistical adaptations, and competitive packages are needed within the trucking industry now more than ever.

->*Used Truck Prices Continue to Skyrocket

Technological and Logistical Adaptations

During COVID-19, the logistics were constantly changing, leaving fleet operators looking for the most efficient way to deliver goods. Fleet carriers, suppliers and drivers were forced to adopt new technologies in order to communicate and operate.

Support teams scrambled to set up shop from their new home offices, onboarding and training employees in tandem on complex software applications to optimize routes, and learn contactless payment systems to reduce exposure.

All the headaches and changes have to lead to a safer, happier, and more productive supply chain and delivery system. The dream of being able to bump the docks and roll onto the next load and enjoy the high tide of “The Era of Post COVID Trucking” is alive as well.

The Future Looks Bright

“We’re just in the beginning stages of this very robust recovery,” said Bob Costello, chief economist at American Trucking Associations. “Some younger people have never seen an economy grow like this before,” he said. “People in their 20s and early 30s have never seen anything like this over a sustained period of time.”

The trucking industry will continue to experience growth in the coming months as long as fleets continue to hire more drivers and balance out the supply and demand issue. Enticing workers to become professional drivers will be (and has been) the primary obstacle for the freight market.

“I’m hopeful that we’ll start seeing people come back into the job market … and we get a closer balance between supply and demand, and that holds up in ’22 so that we don’t see rates come down too substantially and put the market into another freight recession like we saw in 2019,” said Hugh Ekberg, CEO of diversified carrier CRST.

Want more news like this?