Are you a truck driver for a small trucking business or an owner-operator? You’ll face various challenges along the road, and one of them is the dreaded dead truck battery. But learning how to jump-start a semi-truck will give you the confidence you need to deal with this common issue.

This article walks you through everything you need to know, from gathering the right tools to knowing when to call a pro. Our jumpstart for semi-truck step-by-step guides and handy tips will get you back on the road again quickly and safely.

Equipment Required to Jump-Start a Semi Truck

Semi-truck repair insurance does not cover dead batteries. Fortunately, once you know how to jump-start a semi-truck, it’s often a cheap and simple fix. But jump-starting a semi truck requires more than standard automotive tools.

You need heavy-duty jumper cables that can handle large electrical loads and a donor vehicle with a compatible electrical system. You may also want to wear safety glasses and gloves.

Many operators carry a commercial-grade jump starter or portable power pack, which provides a powerful and often safer alternative. Other helpful items include a battery terminal brush and a voltage meter for diagnosing battery issues.

Choosing Heavy-Duty Jumper Cables

The most important thing about jump-starting your truck is that you must use heavy-duty jumper cables.

Light-duty cables designed for cars and vans won’t work on a semi truck. Most semi trucks have 3 or 4 12-volt batteries. Each is rated at around 1000 cranking amps. Therefore, choose cables rated for 1000 amps or more. Use cables at least 20 feet long so you can easily reach between vehicles.

Use 100% copper or high-quality copper-clad aluminum cables. Copper conducts electricity better and lasts longer. Make sure the insulation resists oil, heat, and abrasion. Use clamps that grip battery terminals securely.

Tools Needed for Jump Starting a Semi Truck

In addition to heavy-duty jumper cables, keep the following tools handy:

- Battery terminal cleaner or wire brush. This removes corrosion for better connections.

- A multimeter or voltmeter. This measures the voltage before and after the jump-start.

- Work gloves and safety goggles. They protect hands and eyes.

- Portable jump starter (optional): It offers a self-contained solution without needing another vehicle.

- A flashlight to illuminate dark areas under the hood. This is even more useful if attempting a jumpstart in the dark of night.

These tools ensure you can jump-start your semi truck safely and efficiently.

Safety Measures and Precautions

Working around high-voltage systems can be dangerous if you don’t follow proper safety steps. Before you get started, take these precautions:

- Verify that the donor vehicle has an equal or higher voltage system.

- Turn off both vehicles before connecting the jumpstart cables. Set both trucks to neutral or park. Engage the parking brakes.

- Remove metal jewelry and keep tools away from terminals.

- Avoid leaning over batteries, and wear protective gear like gloves and goggles.

Step-by-Step Guide to Jump-Start a Semi Truck

The life of a trucker can be both exhilarating and challenging. Different truck types, routes, and roles mean that trucking can be a different experience for everyone. But getting sidelined by a dead battery frustrates every trucker.

If your truck won’t start or struggles to start, dead or weak batteries may be the cause. It’s best to use another truck as the donor vehicle or a dedicated jump starter designed for heavy-duty vehicles. A jumpstart is the quickest and cheapest solution.

Follow these steps carefully, and you’ll know how to jump-start your semi truck safely.

Step 1

The jumper cables have to reach both vehicles’ batteries, so position the truck that will be jumpstarting you as close to your semi as possible. However, the vehicles must not touch each other. Turn off both trucks and set them in neutral or park.

Step 2

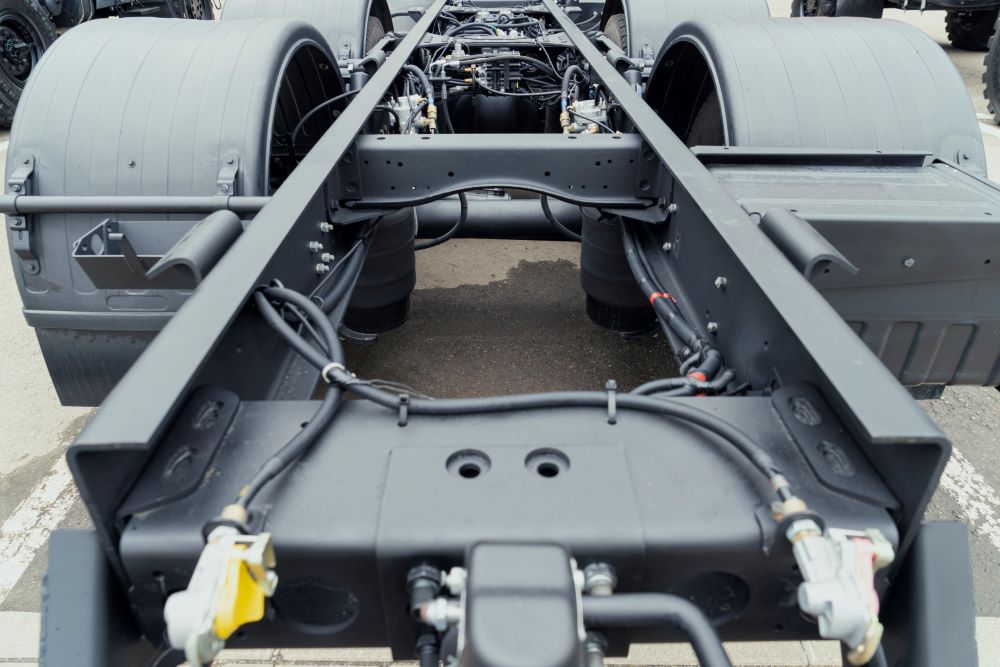

Semi-trucks often have dual batteries or multiple batteries connected in series to meet the high power and performance demands of their engines. Open the trucks’ hoods and locate all batteries. Ensure that you understand your battery configuration before attempting a jumpstart.

Step 3

Inspect the batteries closely and check for battery acid leaks and cracks. If you find any damage, leaks, or cracks, don’t continue. The battery needs to be safely disposed of and replaced. Check the battery terminals for signs of corrosion. If you detect corrosion, clean the terminals with a wire brush to remove it.

Step 5

Once you have determined that the battery has no leaks or cracks and is free from corrosion, you may connect the jumper cables:

- Clamp a red (positive) cable to the positive terminal of the dead battery, and the other red one to the positive terminal of the donor battery.

- Clamp the black (negative) cable to the negative terminal of the donor battery. Attach the other black one to an unpainted metal surface on the engine block or chassis of your semi with the dead battery.

If you are unsure whether or not the battery is flat or if another issue may be at play, check the voltage before and after jumpstarting. However, this is unnecessary if you are certain that a flat battery is the only problem.

Step 6

Start the donor vehicle. Let it run for a few minutes to supply enough current. After a few minutes, try to start your semi-truck. If it doesn’t start, don’t stress; it can sometimes take a while. Just wait a few more minutes and try again.

Step 7

Remove the cables in reverse order:

- Disconnect the black clamp from the chassis.

- Remove the black clamp from the donor battery.

- Remove the red clamp from the donor battery.

- Detach the red clamp from the semi truck battery.

Step 8

Let the semi-truck idle for a while. Keep it running for 15 to 30 minutes to recharge the battery.nDrive it a while or test the battery’s voltage to confirm it’s holding a charge.

How Many Amps to Jump Start a Semi Truck

Semi trucks use powerful batteries. To jump-start a semi truck, you usually need 1000 to 2000 amps. Cold weather may require more. Use a portable jump starter that offers at least 1500 peak amps.

Donor vehicles, like other semi trucks or heavy-duty diesel pickups, can usually provide enough current. Smaller vehicles don’t have the power. Always match your cables and jump starters to your truck’s electrical needs.

Caring for Your Semi Truck Battery

From semi-truck wheel alignment to oil changes, regular maintenance is key to keeping your trucks on the road. But don’t forget about battery maintenance and care. Take care of your semi-truck batteries to reduce the need for future jump-starts.

- Inspect connections: Tighten loose cables and clean corrosion.

- Check fluid levels: Add distilled water to non-sealed batteries if needed.

- Test voltage regularly: Use a multimeter to verify the charge.

- Avoid deep discharges: Turn off accessories when the engine isn’t running.

Signs of Battery Failure

Watch for these warning signs:

- Dim headlights or dashboard lights

- Slow engine cranking

- Clicking noise when turning the key

- Accessory malfunctions

- Swollen or leaking battery case

Replace the battery if you spot these symptoms.

Understanding the Electrical System of a Semi Truck

To know how to jump-start your semi truck, understand its electrical setup. Most semis use 12-volt or 24-volt systems powered by two 12-volt batteries.

These systems supply power to the ignition, lights, refrigeration units, and electronics. Issues with alternators, voltage regulators, or wiring can affect the entire truck. Know how the parts work together to diagnose issues and avoid repeated jump-starts.

When to Call a Professional

Call a professional if you experience the following:

- Remaining uncertainty about how to jump-start your semi-truck.

- Battery damage or battery acid leaks.

- The truck won’t start after multiple attempts.

- Strange sounds or the smell of burning.

- You lack a donor vehicle or a high-powered jump starter.

Professionals have the training and equipment to resolve the issue safely.

Conclusion

Knowing how to jump-start your truck is an essential skill for owner-operators and fleet managers. With our guide to jumpstarting a semi and the right tools, you can handle dead batteries efficiently. And our tips for battery care will extend your semi-battery’s life.

But when your problems are bigger than a dead battery, get the funds you need here at Mission Financial Services.

Do you need to do urgent repairs? We offer semi-truck repair loans. Would it be more economical to replace your ailing truck? We’ll start the ball rolling with a loan for a new (or used but new to you) semi-truck. Contact us today for further information and advice.