In 2018 the trucking industry was flourishing. Drivers were earning more than ever before, which quickly drove people into entering the career. But, in 2019, things took an unexpected turn. As things grew, the demand for trucking services declined, leading to more than a thousand trucking companies going out of business. The incident was later coined “the bloodbath of 2019”.

Now, experts are certain another “bloodbath” could be on the horizon. The question is: are they right?

What caused the bloodbath of 2019?

2017 through 2018 was a prosperous time for carriers in the trucking industry, but when 2019 rolled around, the market dried up and led to a period of contraction. This trying time was labeled as a trucking bloodbath due to the operating ratios for dry van carriers averaging over 100%. Carriers also battled oversupply, lack of demand, and fallen investments. In 2018, fleet owners thought it wise to invest in new trucks, but their investments later proved unbeneficial as 2019’s daily truckload volumes were over 4% under 2018’s volumes. Combined, these factors contributed to many trucking companies closing shop and hundreds of industry professionals without a job.

What is causing the latest trucking bloodbath?

The COVID-19 pandemic has wreaked havoc on global freight markets for the past two years. As we’ve attempted to move forward, the market has taken an unfavorable downturn, and the result could be as detrimental as what we saw in 2019.

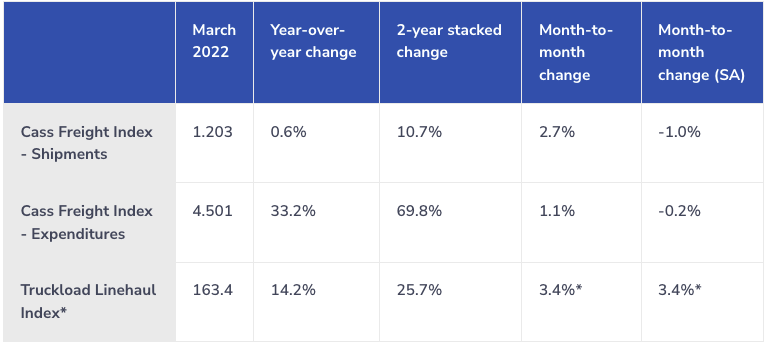

Unfortunately, truckloads have already been relatively soft. While March has proven to be a stronger month in previous years, this year’s has not seen the same surge. A few factors contribute to the market’s current state, and industry professionals worry they could be enough to spark yet another bloodbath.

The contributing factors include:

1. Soft truckload volumes and spot rates

In 2020, inflation began creeping up, causing many consumers to slow down on spending and truckload volumes to lessen more and more. This slow truckload decline only worsened when Russia invaded Ukraine at the start of 2022. For the past few years, industry experts have monitored the dwindling volumes and confirmed that spot rates are also falling fast.

With too many trucks on the road and insufficient freight to load them with, spot rates have skyrocketed. In January, spot rates reached $3.83 per mile, and while they are now down to $3.42 per mile, many experts aren’t exactly sure how the rest of the year will play out.

2. Inflation and high fuel prices

As most Americans know, fuel prices, along with everything else, are higher than it’s ever been. This economic chaos is responsible for curbing consumer spending, therefore affecting truckloads and conjuring the foreseen bloodbath.

3. Consumer spending on the decline

After years spent indoors (thanks to the COVID-19 pandemic), consumer spending on physical goods has slowed, while spending on travel and entertainment has increased. Unfortunately, experiences do not drive much in the way of freight. This spending trend has taken much longer to balance out than most experts expected. In fact, in February, retail sales only reached 0.3%, and they haven’t been much better in the proceeding months.

4. Inventory struggles

The lack of inventory has also played a significant role in why many experts believe another bloodbath is on the horizon. After the pandemic, transshipment infrastructures were clogged up, and freight velocity slowed. Many companies were left with barren shelves and unhappy customers. So, the same companies ordered more stock to safeguard themselves against inventory outages. However, this plan backfired and left businesses with more than they needed after prices spiked and consumers cut their spending habits. Now, experts believe the purchasing of goods will slow to work off excess inventory, and truckloads will continue to remain light.

Will some fleets survive the bloodbath?

So far, most of the larger trucking companies have had decent first-quarter earnings this year. According to market projections, analysts believe that the more established fleets will continue to prosper. However, smaller companies may not be so lucky.

Larger carriers don’t have to worry about spot loads or adjust pricing to account for customer rate cuts, whereas smaller fleets don’t have the same luxury. However, both small and large companies should still be cautious. In 2019, hundreds of fleets went bankrupt, three times as many as the year prior. So, when it comes to fleet survival, it really depends on several factors, such as location and client relations.

Moving forward, owners and operators can expect lower rates and an influx of new fleets entering the market, even after loads soften. And with everyone chasing after high spot volumes, fewer opportunities will be available. And as we saw in 2019, the declining spot rates, dwindling volumes, and increased prices will continue to push fleets into another trucking bloodbath. We all just have to hang on for the ride.

More Like This:

→ Demand for Truckers Dwindles: Recession on the Rise?

→ Where Did All of the Trucks Go?

→ How is the Microchip Shortage Affecting Truck Prices in 2022?