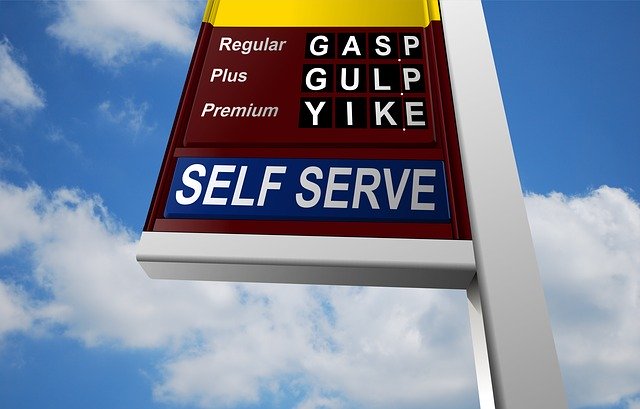

While you may find the picture above amusing, there’s nothing amusing about spending more money for fuel than you need. Your fuel prices are high enough without them receiving any extra help. While many ways exist for you to lower your fleet’s fuel costs, let’s look at six of them right now. Here are the top ways for fleet owners to start conserving fuel.

1. Regular Preventive Maintenance

The number one and most impactful method for reducing fuel costs is implementing an effective regular preventive maintenance (PM) program. Regularly scheduled PM, which can improve a truck’s fuel economy by up to 40 percent, includes maintaining engines and related components as well tires.

- Regular engine oil changes are a must for your trucks because they’re one of the biggest components to PM. The United States Department of Energy states you can increase per-truck fuel economy by as much as two percent by using manufacturers’ recommended engine oil grades. Additionally, look for engine oil labeled as “energy conserving”; it contains friction-reducing additives that help increase fuel economy. Less friction means oil will circulate more easily through the powertrain, which helps improve fuel economy.

- During each of your trucks’ PMs, remove and clean the battery, its connectors, and cables, then load test each one. Something may fail under load, but better in your shop than on the road. Buy your mechanics a battery tester and ensure they know how to use it.

- Trucks’ coolant systems and pressure test caps must be checked during each PM. You don’t want coolant to boil, possibly leading to more costly repairs because of a faulty cap. By caring for your trucks’ cooling systems, you can prevent about 50 percent of potentially major engine failures.

- Don’t forget antifreeze. By “don’t forget,” we mean pay attention to the antifreeze you use prior to adding it to a truck’s cooling system. Newer engines contain metals such as aluminum that don’t play well with some of the chemicals added to engine coolants. Ensure your technicians understand which trucks require which coolants, and ensure they monitor the coolant condition of each truck.

- Lubricate, lubricate, lubricate – and not just engines. Kingpins and universal joints are two major weak points, so take care of them. Although some universal joints have been designed to run hundreds of thousands of miles without trouble, many eventually will require a normal lubricant regimen.

- Let’s talk a little bit about your truck’s tires. The United States Department of Energy maintains that for every one PSI drop in tire pressure, gas mileage will decrease by 0.4 percent. Also, ensure trucks maintain proper wheel alignment, as improper alignment can negatively affect fuel efficiency by up to 10 percent. Needless to say, keep your truck’s tires inflated to the proper pressure and check your wheel alignment.

2. Reshape Your Driving Behavior

The second way to conserve fuel is by addressing driving behavior. The United States Department of Energy has found aggressive drivers can reduce highway fuel efficiency by up to 33 percent and city fuel efficiency by up to five percent.

How can fleet owners shape driver behavior? One way may be to deploy in-cab tools such as coaching apps. Here are three in-cab driver coaching apps that can help increase your fleet’s fuel efficiency. Although they all differ from one another in particular respects, they share several commonalities:

- They draw their truck data directly from the engine control module through a truck’s data port.

- They all provide drivers with indicators regarding their driving performances.

- They all provide driver feedback and score them based upon driving technique, without relying upon fuel consumption data.

Deploying apps like these and having your drivers accept them will work best when you and your company trust your drivers. If you trust them, they’ll trust you and be more likely to accept new technology. Your drivers may even use apps like this to create friendly rivalries to determine who is the most fuel-efficient driver. You could even create company-sanctioned competitions complete with rewards for drivers and driver teams.

3. Fuel-Saving Technologies

Third, evaluate fuel-saving technologies you could implement in your fleet. If you haven’t yet, evaluate telemetry, automated manual transmissions, low-rolling-resistance tires, anti-idling devices, synthetic lubricants, automatic tire inflation systems, adaptive loading axles, full-tractor aerodynamic packages, and aerodynamic skirting for trailers. These are some of the low-hanging fruits you could grab.

4. Consider Truck Replacement

You might consider replacing older trucks with new trucks, even if you might be retrofitting older trucks with fuel-saving specs. Fleets can save $6,048 per truck in the first year of fuel expenditures when replacing a 2015 MY sleeper. That’s a 12 percent increase in fuel economy!

5. Analyze Your Truck Data

Perform some old-fashioned data analysis. How do patterns of fuel usage compare among your drivers on the same or similar routes? Who uses the most fuel, all things being equal? Which trucks present the lowest MPG? Could design or mechanical issues cause any discovered fuel efficiency issues? Maybe the route itself creates a fuel efficiency issue, which leads to the sixth and final top way for fleet owners to conserve fuel.

6. Optimize Your Route Plans

Don’t just rely solely on routing software; perform a route analysis the old-fashioned way. Road quality, traffic conditions, and speed limits influence a truck’s MPG. The shortest distance from one point to another may not always be the most cost-effective. Analyze idling time vs. driving time and design routes to minimize idling as much as possible. Also, look at the terrain your trucks travel on. The EPA’s fuel estimates assume operation on flat surfaces, so if your routes traverse hilly or bumpy roads, your vehicle’s MPG will be lower than the EPA’s ratings for your vehicles.