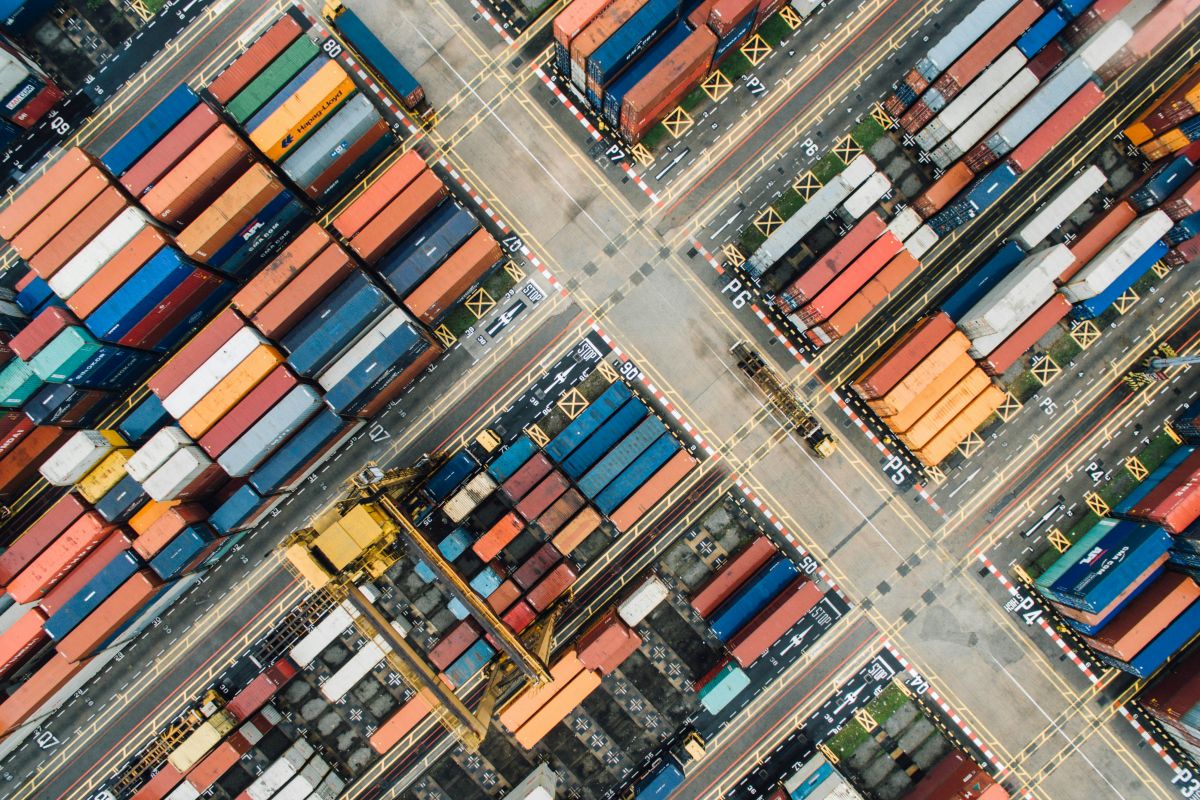

Recently, multiple U.S. ports, which move around 70% of all U.S. trade, have reported record-breaking backlogs that have caused widespread shipping delays across the country. Responsible for approximately half of all U.S. imports, the Southern California ports suffer the most, with over 60 filled cargo ships currently waiting to ship goods. However, other smaller ports throughout the country are also feeling the weight of this issue, including the Port of Savannah, which has over 20 cargo ships waiting to ship.

With the holiday season rapidly approaching, many wonder how this supply chain problem will affect the spirit of the season and if anything can be done to limit the overall impact of this predicament.

→ What We Can Learn From Amazon Prime Day

What’s causing the supply chain problem?

In comparison to 2017 and 2019, the world’s most influential ports experienced above-average wait times and doubled the amount of time for container turnaround in 2021. For example, at the Southern California ports, it took a single ship approximately 6.4 days to dock and unload, as opposed to the standard average of 3.6 days, nearly five days longer than multiple ports, including a 24/7 port in Asia. Recently, these wait times have increased even more, with some ships waiting as many as three weeks.

So, what’s responsible for this uptick in times and averages? The Managing Director of Global Energy Strategy and Digital Intelligence Strategy at the RBC Capital Markets found that most container ships carry around 30% more goods than before due to the intense rise in e-commerce. Another cause is the current employment shortage that is crippling many industries worldwide. Both Long Beach and Los Angeles ports found that they rely on approximately 28% fewer employees at their unloading docks. Pair this dip in employment with the increased freight movements, and you get a supply chain gridlock.

Those working through the supply chain crisis suggest that the only way to reverse the issue is for consumers to reduce the number of purchases they’re making significantly. However, industry professionals fear that the exact opposite will occur as the holiday shopping season commences.

→ Why Owner/Operators Should Run Hard This Holiday Season

How will this impact the holiday season?

With a highly-anticipated increase in in-store and online shopping just around the corner, companies are preparing themselves by stocking up in hopes of avoiding any significant inventory depletions. But with supply chains suffering, most, if not all, industries are expected to be impacted globally. For instance, the US Toy Association, which represents a total of 950 toy firms and sells around $3 billion in toys each year, is anticipating a significant setback in product delivery due to California’s clogged port system.

Outside of the country’s ocean-side ports, many states and their companies struggle with congestion surrounding trucks and freight rails. However, thanks to solid, annual contracts with dedicated shippers, larger retailers won’t need to worry as much as smaller companies. So, how are companies, big and small, preparing for the holiday shopping season?

→ How Truckers Can Prepare for the Holiday Season Amid COVID-19

What can we do to prepare?

Acknowledging that the current situation shaking supply chains is not easily fixable, the President of the United States is working with America’s ports, shipping facilities, and companies alike to prepare for what is expected to be a long holiday season. The President announced that the Port of Los Angeles will commence 24/7 operations, unlocking an additional 60 hours of work. Major shipping companies, such as Walmart, Target, Samsung, Home Depot, FedEx, and UPS, will also increase working hours as we move into the winter seasons. The Biden administration enacted this plan to increase productivity and product movement and relieve the bottle-necked supply chains. When it comes to truck drivers and trucking companies, the administration encourages increased productivity, the ability to unionize, and wages. Biden followed this statement by ensuring federal support would be supported if needed, but he urged companies to step up and help this initiative.

Moving forward, the administration hopes to review the “just-in-time inventory” standards and “invest in greater resilience to resist the kind of supply chain shocks we’ve seen year after year, whether it’s weather, climate change, or cyber-attacks.” Biden also encouraged U.S. companies to limit their reliance on foreign countries and supply chains and instead bring this vital production to America.

→ Long-Term Effects of the Pandemic on the Transportation Industry